Mid-infrared (MIR) fiber lasers have gained increasing prominence in various applications, such as remote sensing, defense security, medical diagnosis, and environmental monitoring, owing to their distinctive absorption properties and atmospheric penetration capabilities. In recent years, soft glass fibers have become ideal gain media for MIR laser sources as it offer good physical properties, thermal stability and chemical durability. Among them, tellurite (based on TeO2) glass is a promising soft glass material with high transparency, high refractive index, high nonlinearity, and low phonon energy. However, tellurite fiber lasers predominantly employ lens coupling for pumping, as research on side-pump couplers based on tellurite fibers remains relatively limited. Typical end-pump combiners, exemplified by tapered fused bundles, although the preparation method is simple and easy to obtain high coupling efficiencies, encounter issues due to fusion splicing and tapering of signal fibers (SFs), including mode-field mismatch, degradation of beam quality, and pump power limitation. By contrast, side-pump couplers offer compelling advantages, including uninterrupted signal fiber, uniform multi-point pumping, and effective thermal management, all of which contribute to their potential applications in MIR fiber lasers.

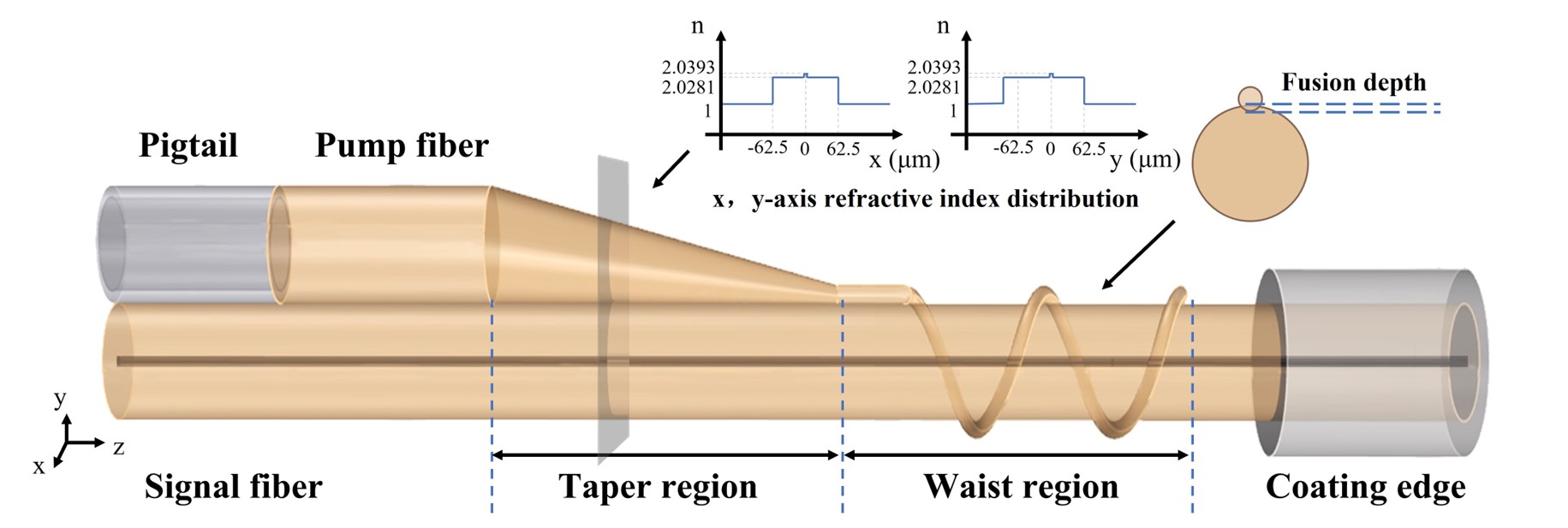

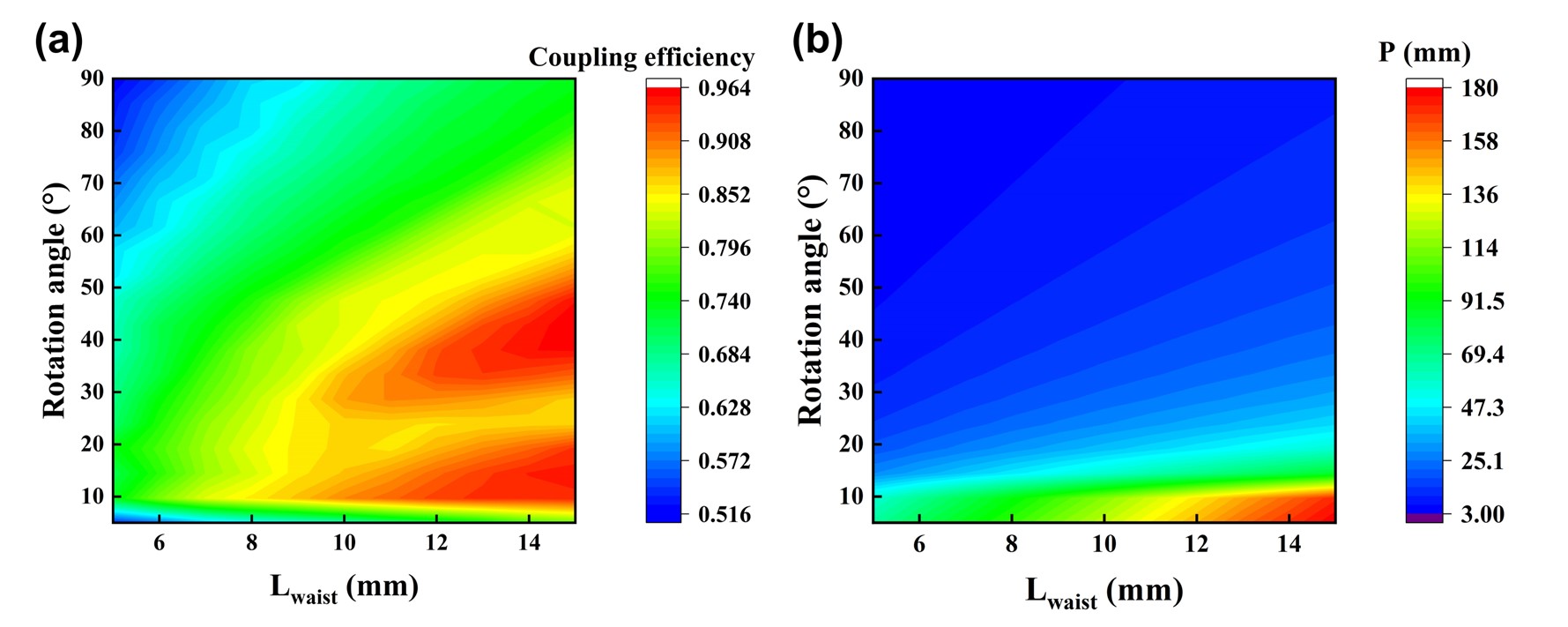

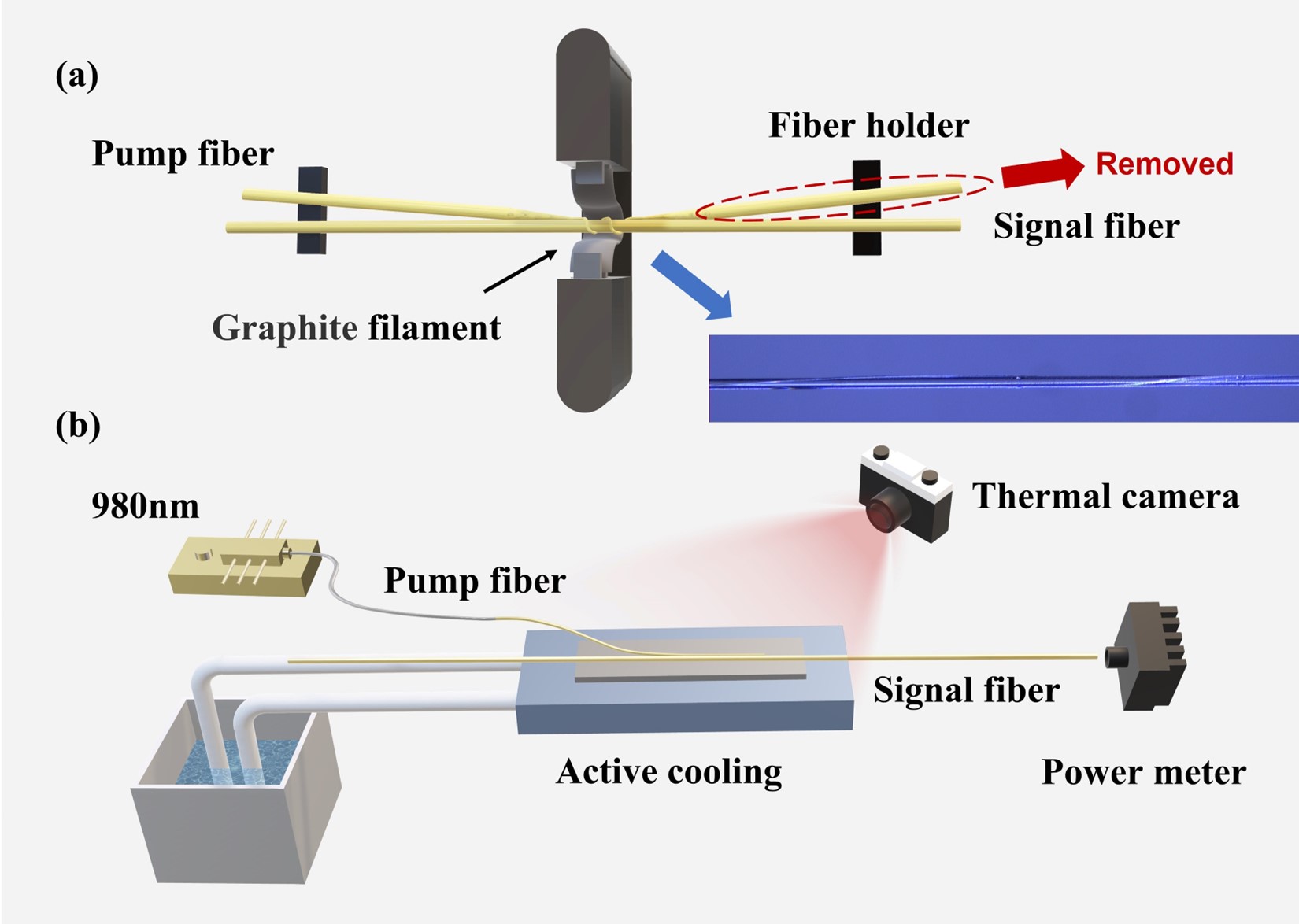

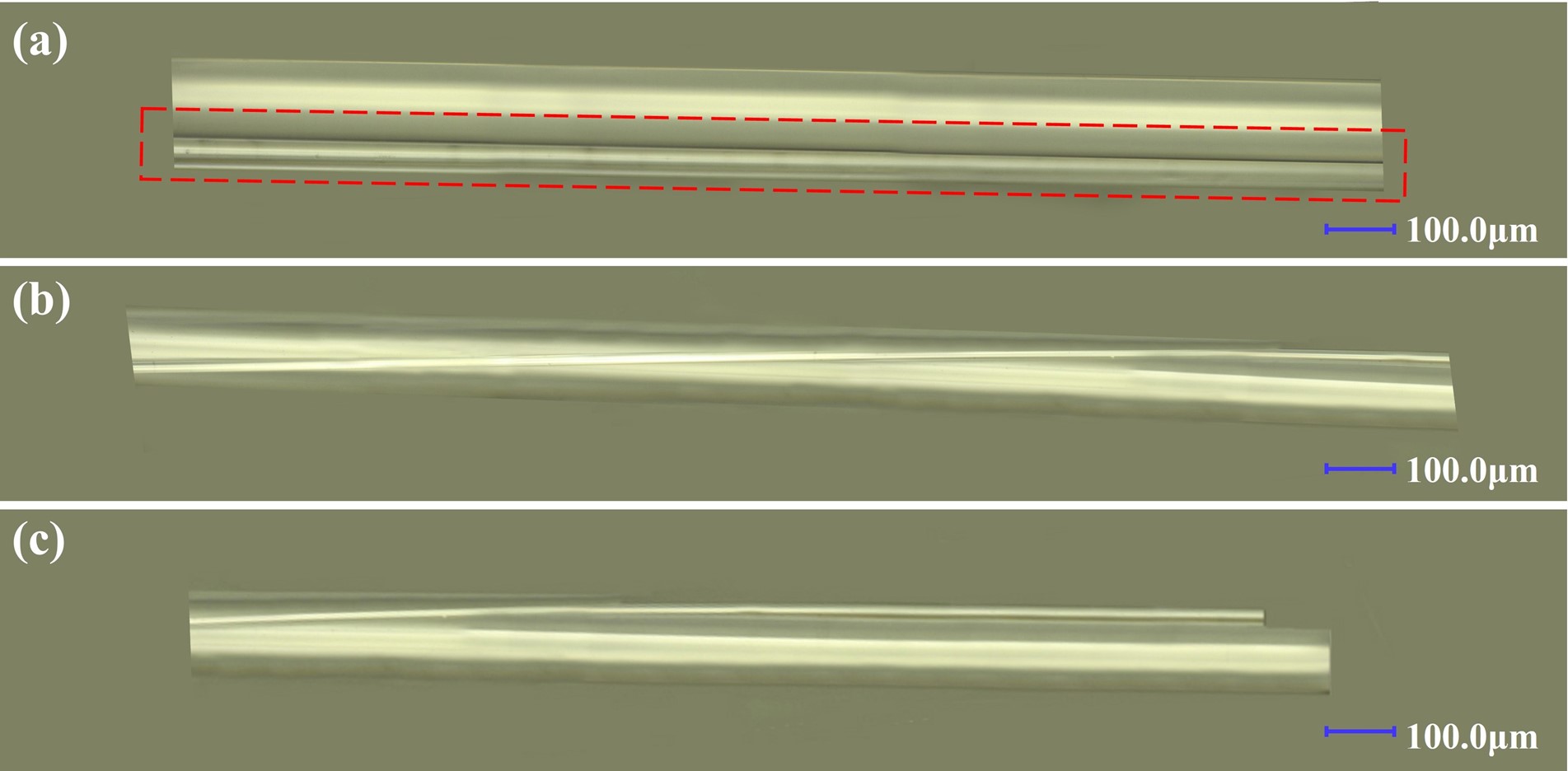

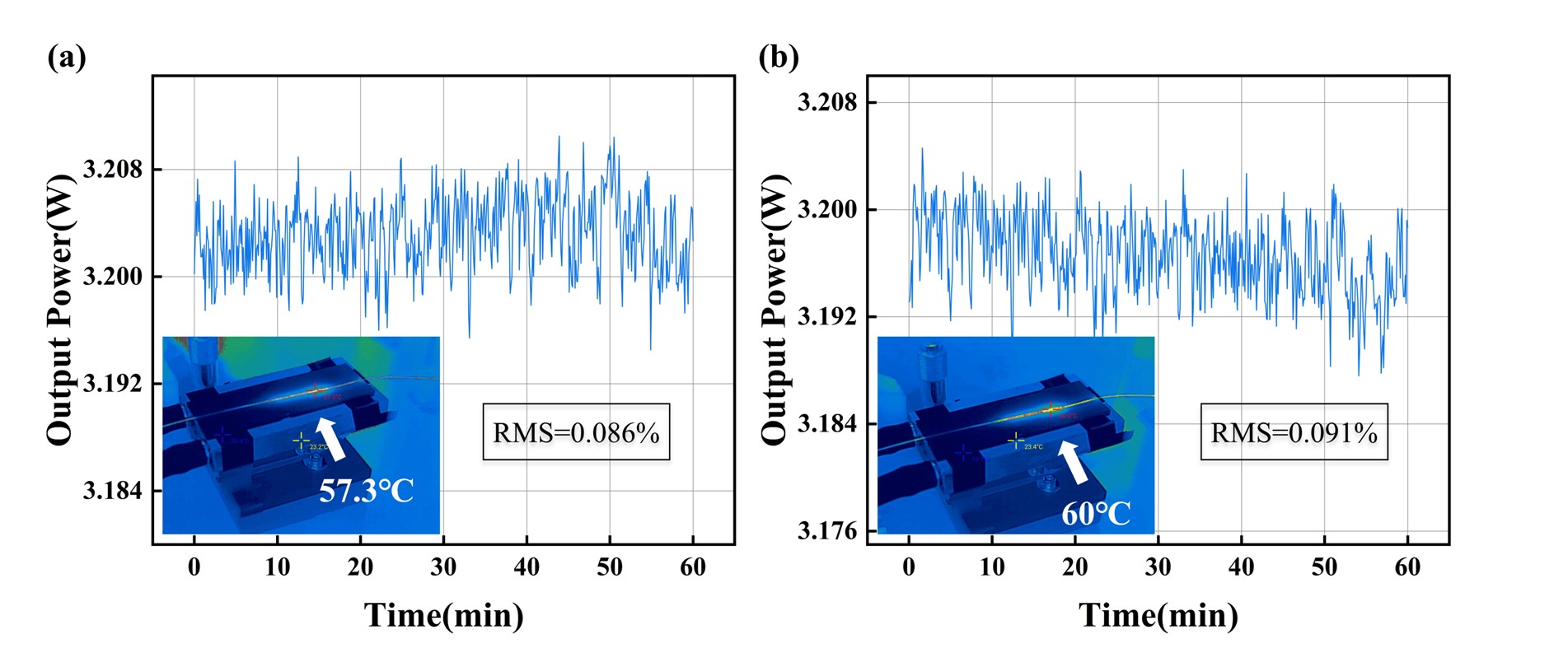

In this work, a (1+1)×1 twisting-fused side-pump coupler was investigated by beam propagation method as shown in Fig. 1. Figure 2(a) and (b) show the changes in the coupling efficiency and P with the increase in rotation angle and Lwaist, respectively. These findings suggest that the coupling efficiency increases with the P-value, exhibiting a relatively high coupling efficiency within a certain range, followed by a decrease. The graphite filament was used as the heating source in the coupler preparation platform to achieve high-quality tapered and fiber fusion coupling, and the coupler was placed on a thermally conductive plate that was cooled by circulating water, and a thermal camera was used to monitor the temperature of the coupler as shown in Fig. 3. Figure 4 illustrates distinct sections of the fused-twisting side-pump coupler when observed under a 500x microscope. As displayed in Figs. 4(a) and (b), the PF attached to the SF, maintaining a parallel alignment at the taper region and gradually twisting around the waist region. The end tip of the waist region after removing the other end of the PF is shown in Fig. 4(c). As depicted in Figs.5(a) and (b), the measured injected pump power to the coupler was 4.2 W. The output power before and after 1 month reached 3.2 W, with RMS stability of 0.086% and 0.091%, respectively. This work provides a meaningful reference for the preparation of soft glass fiber-based couplers, and the prepared couplers are expected to be applied to mid-infrared fiber lasers or amplifiers.

Fig. 1 Diagram of a twisting-fused side-pump coupler.

Fig. 2 (a) Simulation of the relationship between pump coupling efficiency with the rotation angle and Lwaist, (b) Relationship between P with the rotation angle and Lwaist.

Fig. 3 (a) Illustration of the (1+1)×1 side pump coupler fabrication system (inset: partial microscope picture of the side-pump coupler). (b) Experimental setup for coupling efficiency measurement.

Fig. 4 Images showing the different sections of a twisting-fused side-pump coupler: (a) the dotted box shows a portion of the PF taper region along the SF; (b) the waist region of the PF twisting along the SF;(c) the end tip of the waist region after removing the pump fiber;

Fig. 5 Output power of the tellurite fiber coupler over time before (a) and after (b) 1 month for 1 hour while pumping with 4.2W at 980nm.